Engineering:Mechanical system

A mechanical system manages power to accomplish a task that involves forces and movement. Mechanical is derived from the Latin word machina,[1] which in turn derives from the Doric Greek μαχανά (machana), Ionic Greek μηχανή (mechane) "contrivance, machine, engine"[2] and that from μῆχος (mechos), "means, expedient, remedy".[3]

The Oxford English Dictionary[4] defines the adjective mechanical as skilled in the practical application of an art or science, of the nature of a machine or machines, and relating to or caused by movement, physical forces, properties or agents such as is dealt with by Mechanics. Similarly Merriam-Webster Dictionary[5] defines "mechanical" as relating to machinery or tools.

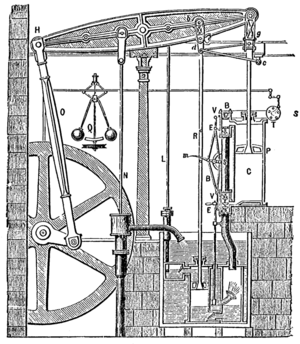

A mechanical system consists of (i) a power source and actuators that generate forces and movement, (ii) a system of mechanisms that shape the actuator input to achieve a specific application of output forces and movement, and (iii) a controller with sensors that compares the output to a performance goal and then directs the actuator input. This can be seen in Watt's steam engine (see the illustration) in which the power is provided by steam expanding to drive the piston. The walking beam, coupler and crank transform the linear movement of the piston into rotation of the output pulley. Finally, the pulley rotation drives the flyball governor which controls the valve for the steam input to the piston cylinder.

Power flow through a mechanical system provides a way to understand the performance of devices ranging from levers and gear trains to automobiles and robotic systems.

Power sources

Human and animal effort were the original power sources for early machines. Natural forces such as wind and water powered larger mechanical systems.

Waterwheel: Waterwheels appeared around the world around 300 BC to use flowing water to generate rotary motion, which was applied to milling grain, and powering lumber, machining and textile operations. Modern water turbines use water flowing through a dam to drive an electric generator.

Windmill: Early windmills captured wind power to generate rotary motion for milling operations. Modern wind turbines drive generators. This electricity in turn is used to drive motors forming the actuators of mechanical systems.

Engine: The word engine derives from "ingenuity" and originally referred to contrivances that may or may not be physical devices. See Merriam-Webster's definition of engine. A steam engine uses heat to boil water contained in a pressure vessel; the expanding steam drives a piston or a turbine. This principle can be seen in the aeolipile of Hero of Alexandria. This is called an external combustion engine.

An automobile engine is called an internal combustion engine because it burns fuel (an exothermic chemical reaction) inside a cylinder and uses the expanding gases to drive a piston. A jet engine uses a turbine to compress air which is burned with fuel so that it expands through a nozzle to provide thrust to an aircraft, and so is also an "internal combustion engine." [6]

Power plant: The heat from coal and natural gas combustion in a boiler generates steam that drives a steam turbine to rotate an electric generator. A nuclear power plant uses heat from a nuclear reactor to generate steam and electric power. This power is distributed through a network of transmission lines for industrial and individual use.

Motors: Electric motors use either AC or DC electric current to generate rotational movement. Electric servomotors are the actuators for mechanical systems ranging from robotic systems to modern aircraft.

Fluid Power: Hydraulic and pneumatic systems use electrically driven pumps to drive water or air respectively into cylinders to power linear movement.

Mechanisms

The mechanism of a mechanical system is assembled from components called machine elements. These elements provide structure for the system and control its movement.

The structural components are, generally, the frame members, bearings, splines, springs, seals, fasteners and covers. The shape, texture and color of covers provide a styling and operational interface between the mechanical system and its users.

The assemblies that control movement are also called "mechanisms." [7][8] Mechanisms are generally classified as gears and gear trains, which includes belt drives and chain drives, cam and follower mechanisms, and linkages, though there are other special mechanisms such as clamping linkages, indexing mechanisms, escapements and friction devices such as brakes and clutches.

The number of degrees of freedom of a mechanism, or its mobility, depends on the number of links and joints and the types of joints used to construct the mechanism. The general mobility of a mechanism is the difference between the unconstrained freedom of the links and the number of constraints imposed by the joints. It is described by the Chebychev-Grübler-Kutzbach criterion.

Controllers

Controllers combine sensors, logic, and actuators to maintain the performance of components of a machine. Perhaps the best known is the flyball governor for a steam engine. Examples of these devices range from a thermostat that as temperature rises opens a valve to cooling water to speed controllers such the cruise control system in an automobile. The programmable logic controller replaced relays and specialized control mechanisms with a programmable computer. Servomotors that accurately position a shaft in response to an electrical command are the actuators that make robotic systems possible.

See also

- History of technology

- Machine (mechanical)

- Linkage (mechanical)

- Mechanism (engineering)

References

- ↑ The American Heritage Dictionary, Second College Edition. Houghton Mifflin Co., 1985.

- ↑ "μηχανή", Henry George Liddell, Robert Scott, A Greek-English Lexicon, on Perseus project

- ↑ "μῆχος", Henry George Liddell, Robert Scott, A Greek-English Lexicon, on Perseus project

- ↑ Oxford English Dictionary

- ↑ Merriam-Webster Dictionary Definition of mechanical

- ↑ "Internal combustion engine", Concise Encyclopedia of Science and Technology, Third Edition, Sybil P. Parker, ed. McGraw-Hill, Inc., 1994, p. 998 .

- ↑ Reuleaux, F., 1876 The Kinematics of Machinery, (trans. and annotated by A. B. W. Kennedy), reprinted by Dover, New York (1963)

- ↑ J. J. Uicker, G. R. Pennock, and J. E. Shigley, 2003, Theory of Machines and Mechanisms, Oxford University Press, New York.

Further reading

- Oberg, Erik; Franklin D. Jones; Holbrook L. Horton; Henry H. Ryffel (2000). Christopher J. McCauley. ed. Machinery's Handbook (30th ed.). New York: Industrial Press Inc.. ISBN 9780831130992.

- Reuleaux, Franz (1876). The Kinematics of Machinery. New York: reprinted by Dover (1963).

- Uicker, J. J.; G. R. Pennock; J. E. Shigley (2003). Theory of Machines and Mechanisms. New York: Oxford University Press.